The Manufacturing Process of Mobile Power Wireless Charging Manufacturers

I. Introduction

Wireless charging technology has revolutionized the way we power our devices, offering convenience and efficiency. This technology allows users to charge their smartphones, tablets, and other gadgets without the hassle of tangled cords and connectors. As mobile devices become increasingly integral to our daily lives, the demand for mobile power wireless charging solutions has surged. This blog post will explore the intricate manufacturing process behind these innovative products, shedding light on the various stages from design to distribution.

II. Understanding Wireless Charging Technology

A. Principles of Wireless Charging

Wireless charging operates on the principles of electromagnetic induction and resonant inductive coupling. Electromagnetic induction involves the transfer of energy between two coils: a transmitter coil in the charging pad and a receiver coil in the device. When an alternating current flows through the transmitter coil, it generates a magnetic field that induces a current in the receiver coil, thus charging the device.

Resonant inductive coupling enhances this process by allowing the transmitter and receiver coils to resonate at the same frequency, increasing efficiency and enabling charging over greater distances. This technology is crucial for the development of more versatile and user-friendly wireless charging solutions.

B. Types of Wireless Charging Standards

Several standards govern wireless charging technology, with the most prominent being the Qi standard, developed by the Wireless Power Consortium. Qi is widely adopted across various devices, ensuring compatibility and ease of use. Other standards include the Power Matters Alliance (PMA) and the Alliance for Wireless Power (A4WP), each with its unique specifications and applications. Understanding these standards is essential for manufacturers to ensure their products meet industry requirements and consumer expectations.

III. Market Overview

A. Growth of the Wireless Charging Market

The wireless charging market has experienced exponential growth in recent years, driven by the increasing adoption of smartphones and other portable devices. According to industry reports, the market is projected to reach several billion dollars in the coming years, fueled by advancements in technology and consumer demand for convenience.

B. Key Players in the Industry

Numerous companies are vying for a share of the wireless charging market, ranging from established tech giants to innovative startups. Key players include Apple, Samsung, and Belkin, each contributing to the development of cutting-edge wireless charging solutions. These companies invest heavily in research and development to stay ahead of the competition and meet the evolving needs of consumers.

C. Consumer Demand and Trends

As consumers become more tech-savvy, their expectations for wireless charging solutions have also evolved. There is a growing demand for faster charging speeds, compatibility with multiple devices, and aesthetically pleasing designs. Manufacturers must stay attuned to these trends to remain competitive in the market.

IV. Design and Development Phase

A. Conceptualization of Wireless Charging Products

The manufacturing process begins with the conceptualization of wireless charging products. This phase involves extensive market research and analysis to identify consumer needs and preferences. Manufacturers must also define their target audience, ensuring that their products align with the expectations of potential customers.

B. Prototyping

Once the initial concept is established, manufacturers move on to prototyping. This stage involves creating initial designs and testing the functionality and efficiency of the wireless charging solution. Prototypes allow manufacturers to identify potential issues and make necessary adjustments before moving into full-scale production.

C. Compliance with Industry Standards

Compliance with industry standards is crucial in the design and development phase. Manufacturers must adhere to safety regulations and certification processes to ensure their products are safe for consumers and compatible with existing devices. This step is vital for building trust and credibility in the market.

V. Sourcing Materials

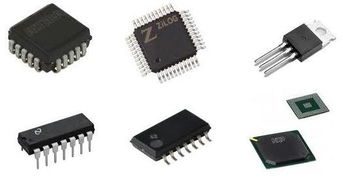

A. Key Components of Wireless Chargers

The manufacturing of wireless chargers requires several key components, including transmitter and receiver coils, power management integrated circuits (ICs), and enclosures. Each component plays a critical role in the overall functionality and efficiency of the charging solution.

B. Supplier Selection and Procurement

Selecting the right suppliers is essential for manufacturers to ensure the quality and reliability of their products. Manufacturers evaluate potential suppliers based on factors such as cost, quality assurance, and delivery timelines. Establishing strong relationships with suppliers can lead to better pricing and more reliable sourcing of materials.

VI. Manufacturing Process

A. Assembly Line Setup

The manufacturing process involves setting up an efficient assembly line. Manufacturers design the layout to optimize workflow, ensuring that each stage of production is streamlined. This setup minimizes delays and maximizes productivity, allowing manufacturers to meet consumer demand effectively.

B. Production Stages

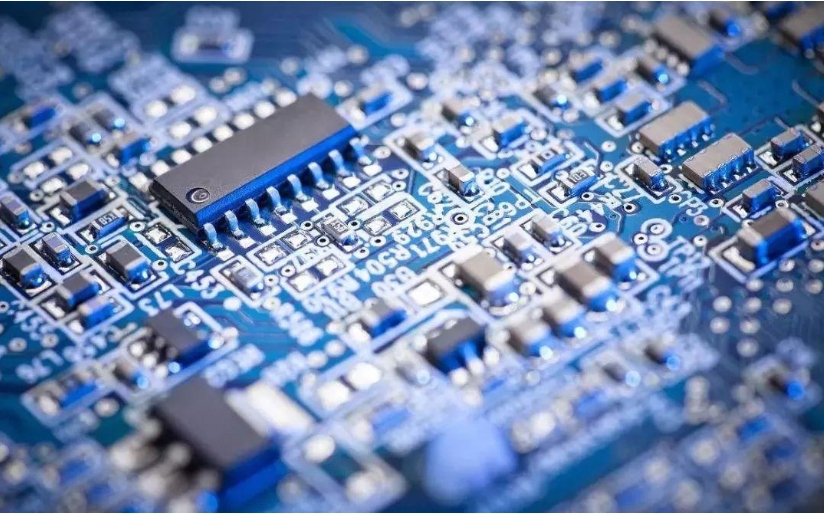

The production process consists of several stages, including coil winding and assembly, circuit board assembly, and the integration of components. Each stage requires precision and attention to detail to ensure the final product meets quality standards.

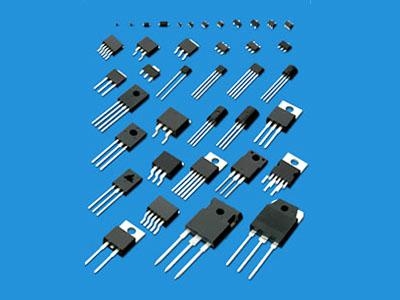

1. **Coil Winding and Assembly**: The transmitter and receiver coils are wound using specialized machinery to ensure uniformity and efficiency. Once wound, they are assembled into the charging pad and the device.

2. **Circuit Board Assembly**: The power management ICs and other electronic components are soldered onto the circuit boards. This stage is critical for ensuring the functionality of the wireless charger.

3. **Integration of Components**: After the individual components are prepared, they are integrated into the final product. This stage involves assembling the enclosure, ensuring that all parts fit together seamlessly.

C. Quality Control Measures

Quality control is a vital aspect of the manufacturing process. Manufacturers implement rigorous testing protocols to ensure the functionality and safety of their products. This includes testing for charging efficiency, safety compliance, and durability. By adhering to strict quality control measures, manufacturers can minimize defects and enhance customer satisfaction.

VII. Packaging and Distribution

A. Packaging Design Considerations

Once the wireless chargers are manufactured, they must be packaged for distribution. Packaging design plays a crucial role in branding and marketing, as well as protecting the product during transport. Manufacturers must consider factors such as aesthetics, functionality, and sustainability when designing packaging.

B. Distribution Channels

Manufacturers have various distribution channels to choose from, including direct sales and retail partnerships. Developing a robust distribution strategy is essential for reaching consumers effectively. Global distribution strategies may also be employed to tap into international markets and expand the customer base.

VIII. Challenges in Manufacturing

A. Technological Challenges

Manufacturers face several technological challenges in the wireless charging industry. One of the primary concerns is improving the efficiency and speed of charging solutions. Additionally, ensuring compatibility with a wide range of devices can be complex, as different manufacturers may use varying technologies.

B. Supply Chain Issues

Supply chain issues can significantly impact the manufacturing process. Material shortages, logistics challenges, and transportation delays can hinder production timelines and increase costs. Manufacturers must develop contingency plans to mitigate these risks and ensure a steady supply of materials.

C. Regulatory Hurdles

Compliance with international standards and environmental regulations poses another challenge for manufacturers. Navigating the complex landscape of regulations can be time-consuming and costly, but it is essential for ensuring the safety and legality of products in various markets.

IX. Future Trends in Wireless Charging Manufacturing

A. Innovations in Technology

The future of wireless charging manufacturing is bright, with numerous innovations on the horizon. Manufacturers are exploring faster charging solutions and the integration of wireless charging with other technologies, such as solar power. These advancements will enhance the convenience and versatility of wireless charging products.

B. Sustainability in Manufacturing

Sustainability is becoming increasingly important in manufacturing processes. Companies are seeking eco-friendly materials and practices to reduce their carbon footprint. Emphasizing sustainability not only benefits the environment but also appeals to environmentally conscious consumers.

C. Market Predictions and Growth Opportunities

As the wireless charging market continues to grow, manufacturers have ample opportunities to expand their product offerings and reach new customers. By staying attuned to consumer trends and technological advancements, manufacturers can position themselves for success in this dynamic industry.

X. Conclusion

In conclusion, the manufacturing process of mobile power wireless charging manufacturers is a complex and multifaceted endeavor. From understanding the technology behind wireless charging to navigating the challenges of production and distribution, manufacturers must be agile and innovative to succeed. Continuous innovation and a commitment to quality will be essential for meeting the evolving needs of consumers and ensuring the future growth of the wireless charging market. As technology advances and consumer expectations rise, the potential for mobile power wireless charging manufacturers is limitless.